Recently Published Thesis/Dissertation on Machine Learning | 10.01.2020

This praxis is of special interest for operation managers, sustainment engineers, and lifecycle logisticians dealing with sustainment-dominated (SD) systems and for others who are involved and/or interested in managing obsolescence.

An example of SD systems is the military’s Command, Control, Communications, Computers, and Intelligence (C4I) systems with an extended utilization of life. The deployed C4I Sub-systems are complex and require many software applications to run effectively and efficiently. A faulty unit in a sub-system can cause the entire system to become unusable. Military systems use highly advanced technologies and have a longer lifecycle than their constituent products. The lifecycle of complex military systems can extend to go over 30 or even more than 40 years. New product development or modifying the existing product in these systems have high cost and/or long times associated with it. As a result, the focus of customers or manufacturers is more on sustaining the products. Consequently, SD systems will eventually fall behind the technology. Obsolescence is one of the main problems that these systems will face during their lifetime……

Abstract

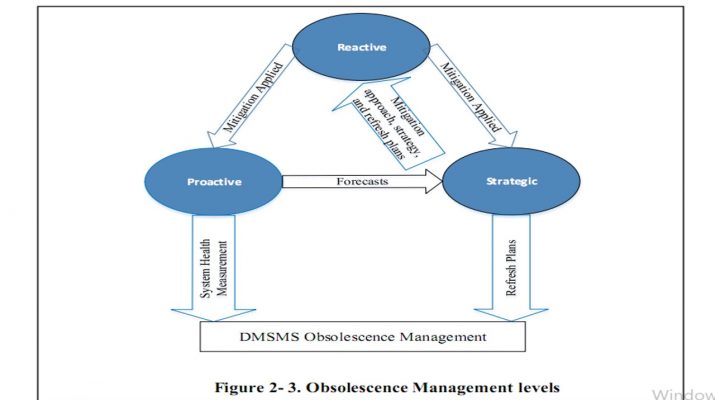

The focus of this praxis was on Diminished Manufacturing Sources and Material Shortages (DMSMS) type technology obsolescence of military systems. Military’s inability to predict the procurement lifetime of their electronic units leads to reactive obsolescence management and ultimately increased sustainment cost and readiness degradations. The program managers and operation leads at General Dynamics Information Technology (GDIT) would like to improve the process used to predict DMSMS obsolescence for their Navy Command, Control, communication, computer, and Intelligence (C4I) program subsystems they are under contract to sustain. This paper has responded to GDIT’s process improvement initiative by recommending a machine-learning algorithm that can be used to develop a predictive model capable of making inferences about procurement lifetime of electronic units in sustainment-dominated (SD) systems. The researcher hypothesized that manufacturer, unit categorization, market value, reliability data, and unit age are the most significant predictor of electronic products procurement lifetime in SD systems. All the pros and cons were considered to improve the existing DMSMS obsolescence processes at GDIT. The researcher hypothesized again that the proposed machine learning prediction model in this praxis will enable provisioning solutions to obsolescence risk, which will yield in higher cost avoidance than current reactive engineering solutions.

Historical data were collected from GDIT repository of a Navy program obsolescence and configuration management data. The researcher used multiple linear regression with backward elimination method for determining the most important factors in determining procurement lifetime of electronic units in SD systems. Also, utilized machine learning methods such as Random Forest (RF), Neural Networks (NN), and K-Nearest Neighbors (KNN) for determining the most applicable model for predicting procurement lifetime. Finally, presented a case to show the benefits of a DMSMS predictive tool in terms of cost avoidance.

Based on the statistical data, the researcher illustrated that a machine learning-based prediction model could forecast procurement lifetime of Navy’s C4I electronic units with higher accuracy than manufacturer’s quotes. Recommendations for future work included using larger sample size and repeating machine learning algorithms on different SD systems.

Dehlavi, Kamran. The George Washington University, ProQuest Dissertations Publishing, 2020. 27664295.

Source: search.proquest.com